Investors

Download our Investment Plan

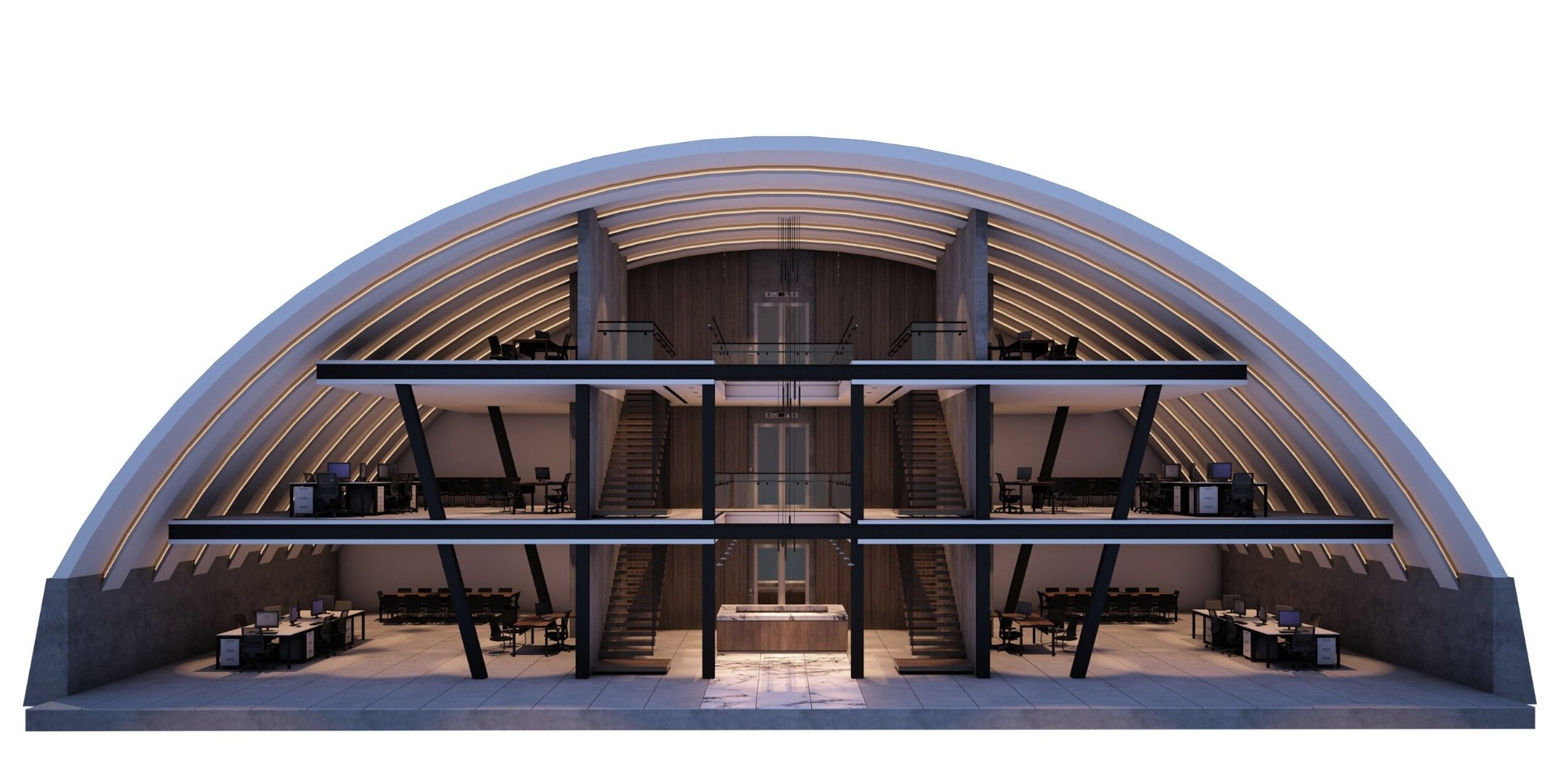

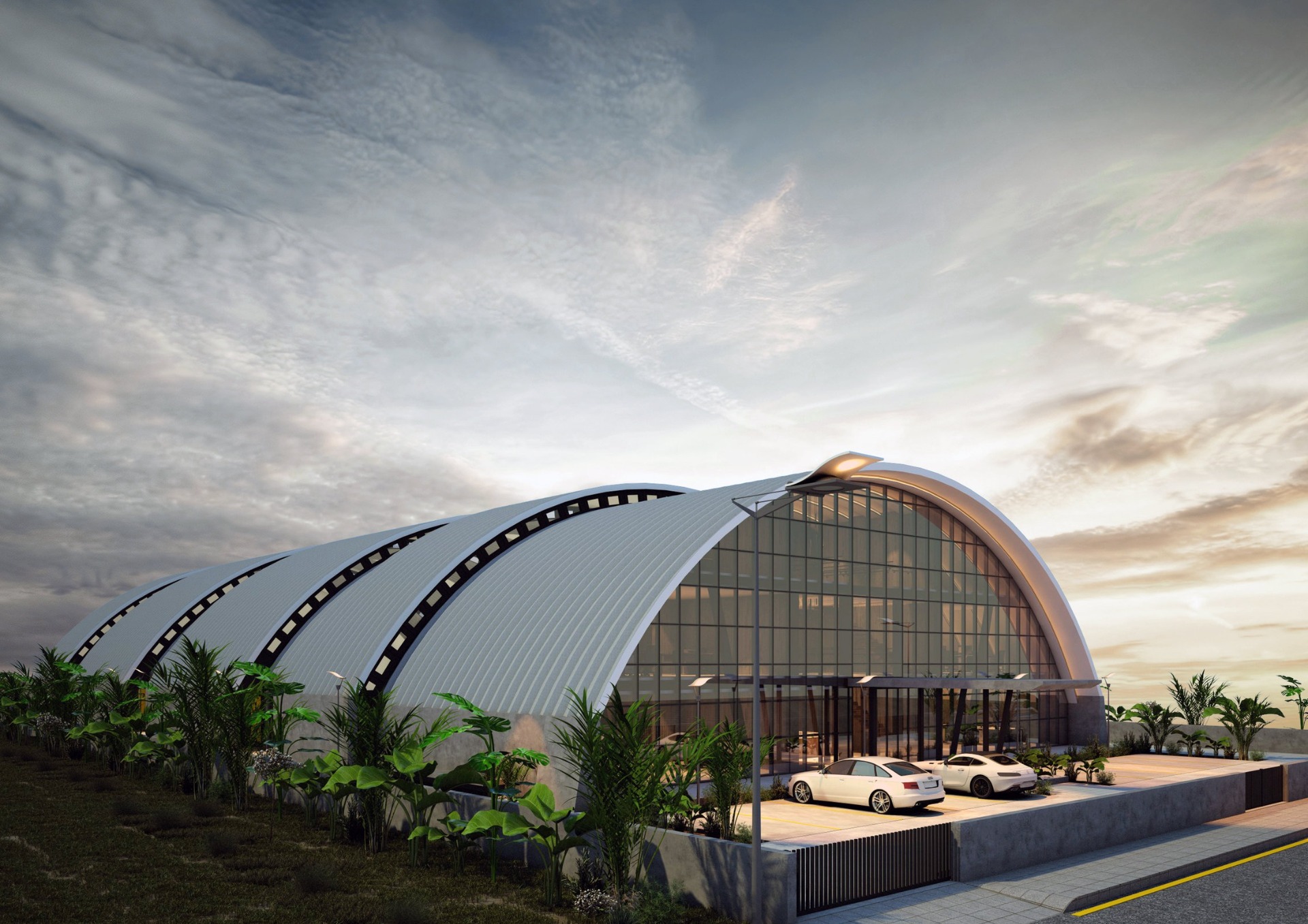

R&D Offices

MYRMIDON facilities are designed for rapid-deployment research campuses that grow with the roadmap. Arch-steel structures deliver wide, column-free interiors for laboratories, AM bays, and test lines. They assemble quickly with small crews and allow straightforward expansion as programs evolve. The shell uses corrosion-resistant panels to keep maintenance low and manage thermal loads, while tailored insulation and interior fit-outs meet clean-build, acoustic, and fire-safety targets. Utilities, crane loads, and service corridors are planned from day one so equipment rolls in and switches on fast. The result is a resilient, code-ready envelope that turns capital into working capacity, quickly and efficiently with immediate expansion capabilities whenever required.

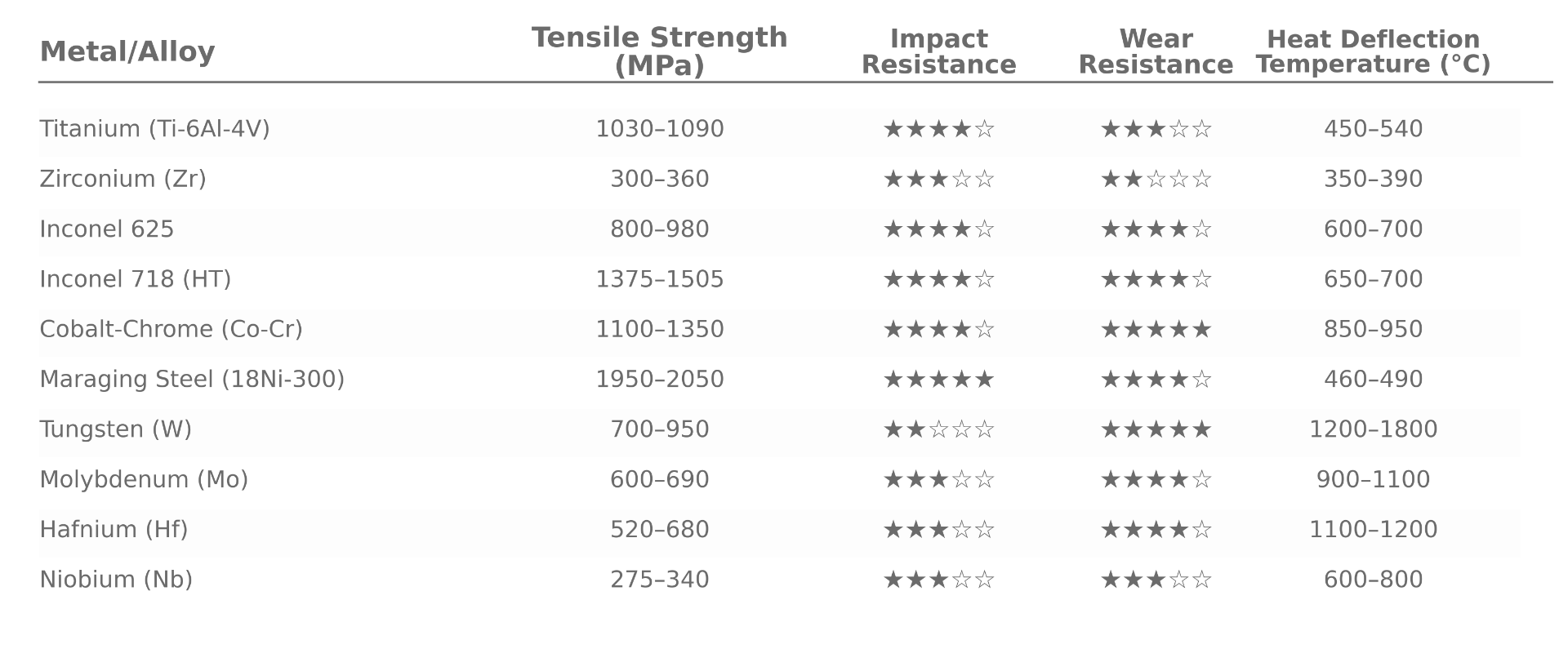

Special Metals Printing for Prototypes

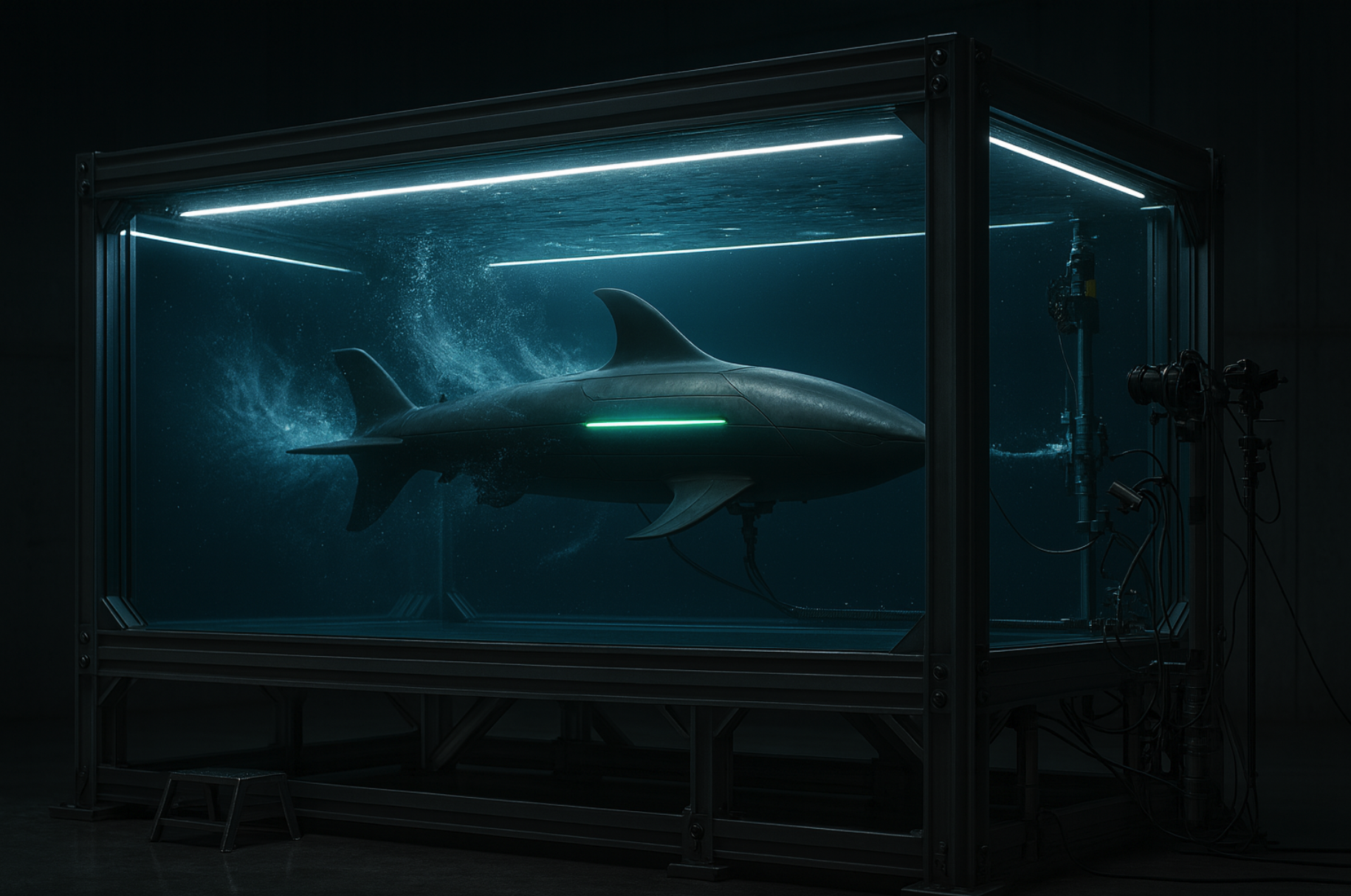

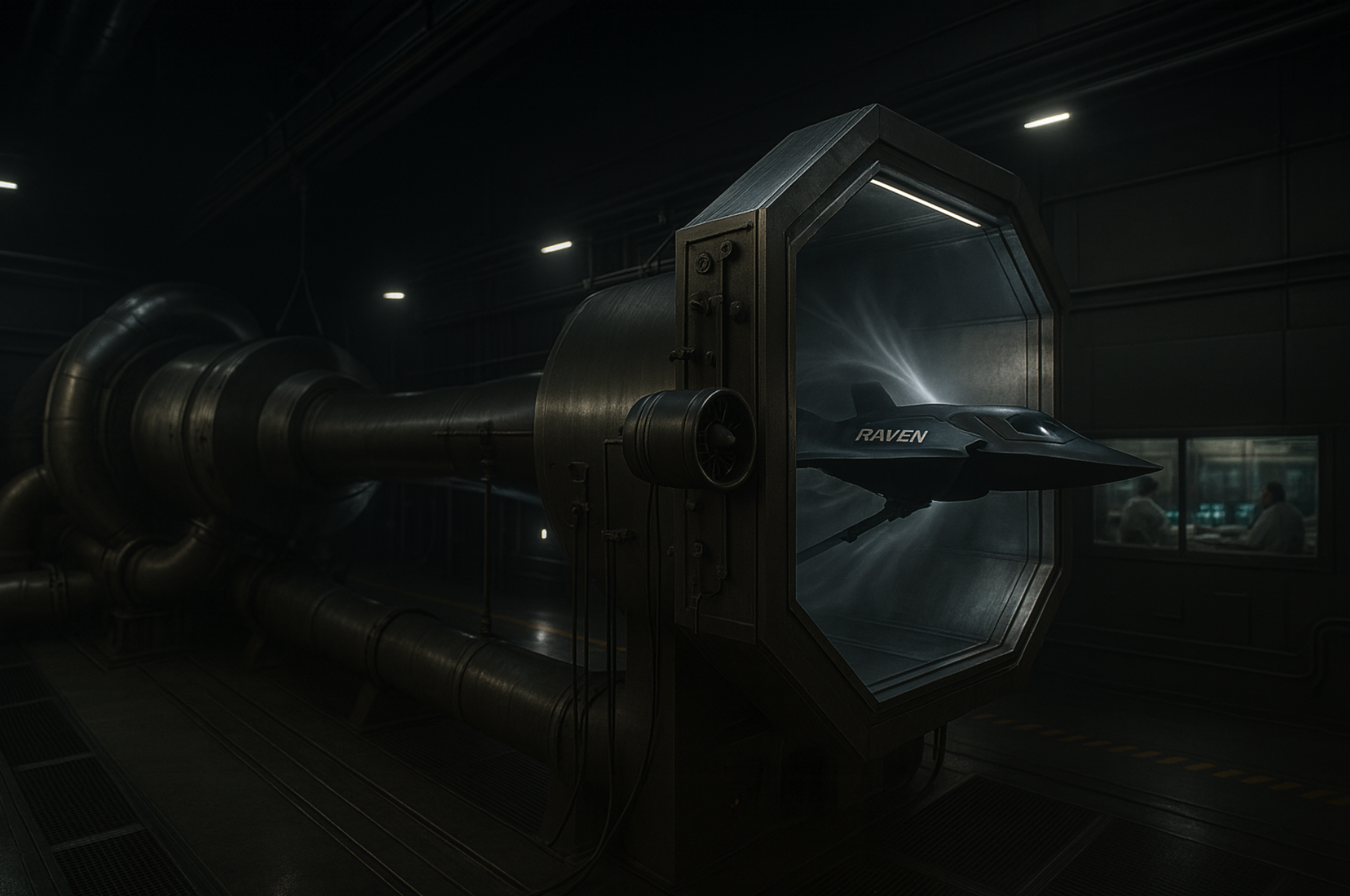

From hypersonic airframes to deep-water propulsion, we print hard-to-machine alloys into testable geometry fast. Electron-beam and laser powder-bed systems, plus DED for large sections, let us build dense, heat-resistant parts with controlled microstructure and repeatable mechanicals. Typical workstreams include topology-optimized housings, combustor liners, turbine and pump hardware, nozzle inserts, heat shields, and structural brackets, all delivered with the post-processing they need (HIP, solution/age, surface finishing, NDI). From hypersonic engines and UAVs to underwater propellers and UUVs, loitering munitions, aircraft spares, energy-weapon crafts, and satellite hardware, we deliver mission-specific defense parts and artifacts.

Carbon Printing for Defense MVPs

We add the engineering that makes prints field-worthy. Parts are designed for additive from the start to hit stiffness and mass targets without overbuilding. The pipeline is fast and surfaces get the right post-processing. First articles ship with dimensional checks and a short test plan (fit, torque, and thermal soak as needed) so you can execute a same-day install or range evaluation. When a design locks, we freeze the model and stand up extra print cells for surge capacity or forward deployment, pushing the exact same settings from prototype to production, ready to scale.

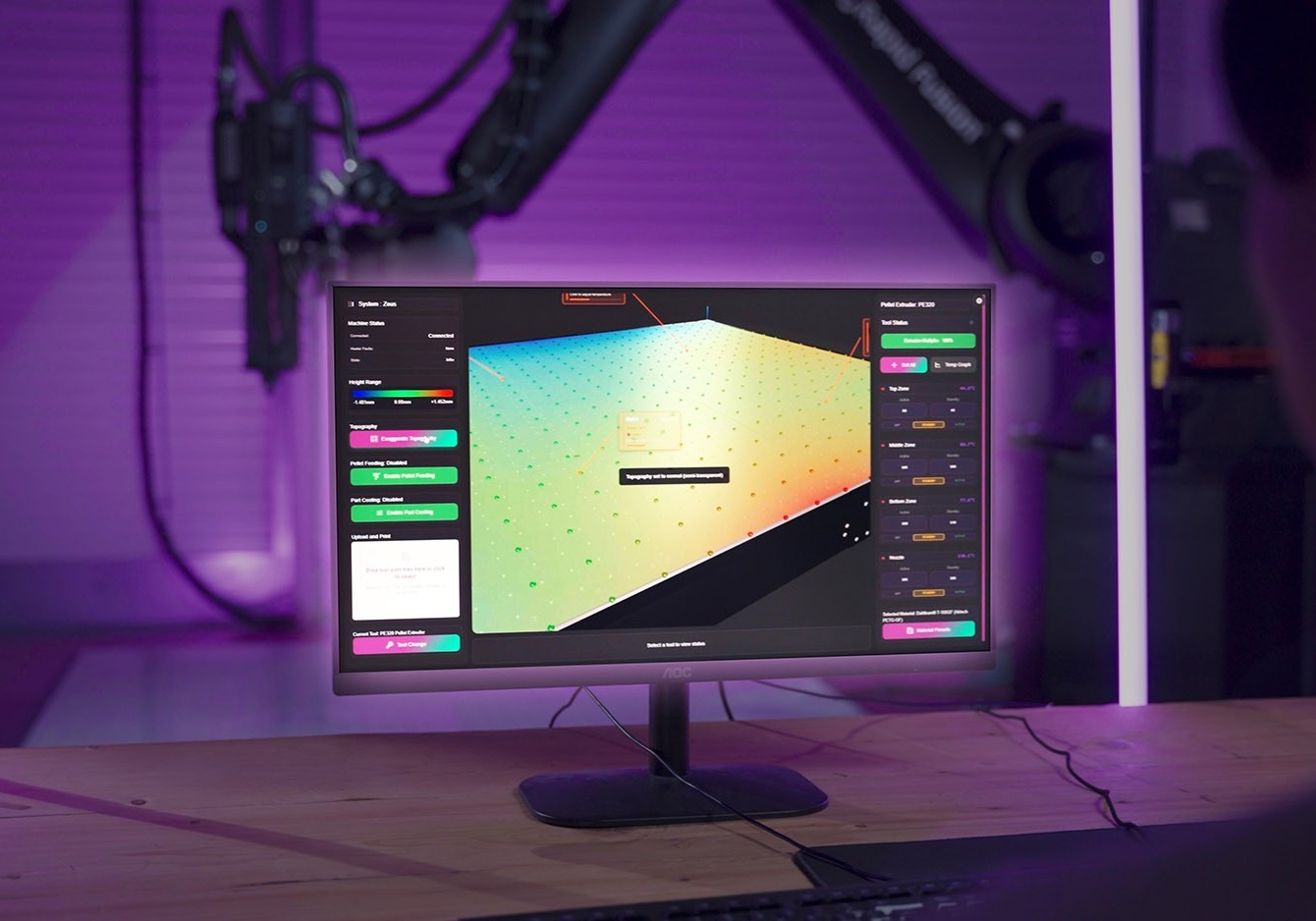

AI Software for Rapid 3D Design

We turn ideas into parts fast, by combining an AI-driven multi-axis path generator with a robotics CAM environment that simulates, validates, and executes prints. Through a visual workflow, designs convert directly into collision-free motions, with a digital twin checking reach, singularities, and flow consistency before anything moves on the floor. The system unifies large-format printing with machining and scanning, synchronizes robot speed to extrusion throughput, optimizes retractions for clean surfaces, and streams real-time telemetry for quality assurance. Shorter programming time, fewer failures, and production-ready designs you can trust across carbon-polymers and metals, ideal for big, complex parts where conventional slicers fall short.

Test Tank for UUVs & Wind Tunnel for UAVs